I. product introduction

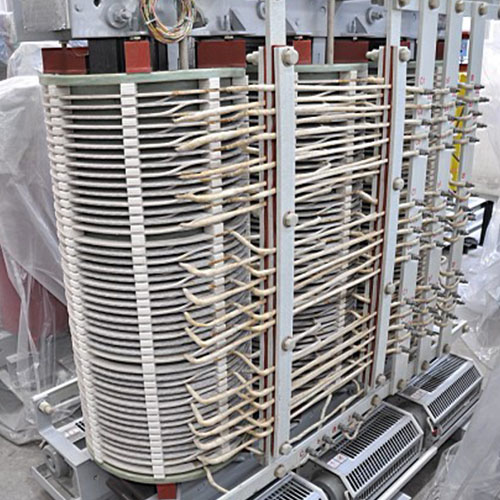

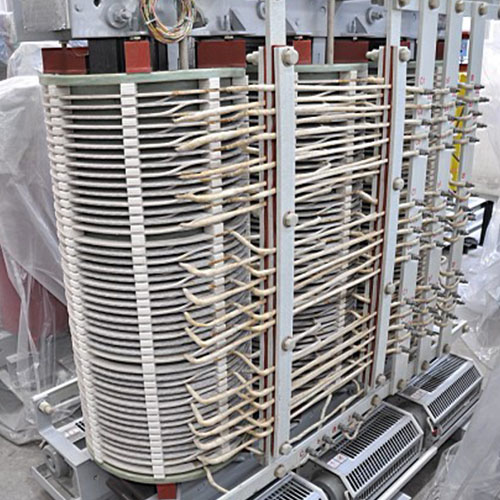

traction rectifier transformer

Converter technology is a kind of alternating current and direct current mutual conversion technology, including rectifier, inverter and frequency conversion. Converter transformer is a main equipment to meet the above functions. In urban subway and light rail, the converter transformer specially used for rectifying is called traction rectifier transformer.

Power distribution transformer

In the normal operation of urban rail transit, in addition to the traction power, there are many power equipment in environmental control and system services, such as: fans, elevators and other power equipment and lighting equipment. These equipment generally use three-phase 380V or single-phase 220V AC. The function of two power lighting transformers in step-down substation is to reduce the medium voltage level input by regional substation or substations into low-voltage alternating current, and distribute power for various equipment through distribution (substation) room.

Transformer for regenerative braking energy feed system

When the vehicle is braked, the redundant regenerative braking energy makes the DC grid voltage rise. Due to the frequent starting and braking of rail transit vehicles, the braking energy is quite considerable. The regenerative braking energy feedback system makes full use of the electric energy generated by train braking, improves the utilization rate of regenerative energy, has good energy saving effect, and can reduce the capacity of train braking resistance. Its energy is directly fed back to the power grid, and does not need to be equipped with energy storage elements or absorption resistors. Therefore, the ambient temperature With the development of smart grid and the improvement of energy-saving awareness, regenerative braking energy feed system will become the main direction of future technology development because of its high economy and energy utilization rate.

SVG device

In the early stage of metro operation, due to the small traction and power load, the charging reactive power of 35kV Cable is significant, resulting in partial capacitive reactive power can not be neutralized, so it is returned to the power system. As a result, the power factor of the main substation can not meet the requirements of the power sector. In order to improve the power factor of the subway system, a kind of facility which can compensate both capacitive reactive power and inductive reactive power is needed. With the development of power electronics, static var compensation device (SVG) is widely used in rail transit industry. It can timely send or absorb the reactive power required by the system according to the power factor of the system to ensure that the power factor remains at a required level. The device is designed to install one set on two 35kV busbars of the main substation.

II. Product features and advantages

Shunte Electric is the first enterprise to develop and develop traction rectifier transformer in China. In 1998, it was established in the international 12 pulse rectifier technology base

On the basis of this, Shunte electric took the lead in the development and development of 24 pulse rectifier transformer and successfully connected the network in Guangzhou Metro Line 1. In addition to the general advantages of dry-type transformer, the R & D and production of traction rectifier transformer, power distribution transformer, transformer for regenerative braking energy feed system and SVG device also have the following unique advantages:

Low noise environment protection

Shunte Electric has developed a low-noise core structure by applying the breakthrough technical achievements in noise research made by postdoctoral workstation for many years, which has reached the noise level required by urban residential quarters.

Strong short circuit resistance

In order to provide the anti short circuit ability of the transformer, Shunte electric uses the computer to check the anti mechanical ability of the transformer structure, check the stress of the transformer during the short circuit, and adopts the special pouring process to greatly strengthen the anti short circuit ability of the transformer.

High insulation strength

Shunte electric application and Tsinghua University jointly developed the simulation analysis and calculation software of shock wave process, which can accurately locate the local position of high voltage and voltage gradient, strengthen the insulation, improve the lightning impulse resistance ability of transformer, reasonably improve the distribution of electric field, and theoretically reduce the partial discharge to the minimum value.

Static mixing and continuous on-line degassing technology are adopted to ensure the reliability of products.

Superior moisture resistance

Reasonably design the insulation structure, adopt the epoxy resin thin insulation, static mixing and patented technology, and spray RTV on the coil surface

Water material, excellent moisture-proof performance, transformer can also be equipped with condensation controller and heater, increase the safety factor.